Completed External projects.

• PLD-based custom CCD timing generator and digitizer on a 4-layer PCB. The system used a CPLD to generate multiple clock phases and some application-specific TI chips to drive the CCD. A high-speed ADC was used to digitize the CCD outputs.

• Power supply (solar-cell charger and three switch-mode supplies) and signal switching design for a portable spectrometer.

• Detailed design proposal for an electro-optical spacecraft attitude sensor.

• The firmware (‘HC05) for a parking lot ramp snow melter.

• An arbitrary digital output suite for a customer to use to control multiple chip-level cameras. This was an ISA-based board with plug-in daughter boards to meet the required flexibiity.

• Major portion of the firmware (‘HC05) for a golf-course-grade riding lawnmower.

• PLD-based programmable timing generator for an EL display manufacturer’s test system.

• Did the preliminary design for a snow-height determining system.

• Designed a LED tail/brake/license light for a motorcycle accessories manufacturer. Because it is a low volume, high quality product, the manufacturing is done in-house.

• Digital portion of a spacecraft-bourne optical sensor test circuit. Built onto a US experiment platform which was launched in a UK satellite, on a French rocket.

• Maintainability analysis for an industrial high pressure water-jet cutter. This was a rack full of VME boards that were thought to be becoming scarce.

• Large CPLD (Cypress CY37 series) for an Atmel ARM single-board computer, as well as much of the (GCC-compiled under Cygwin) low-level software for the processor.

• PIC-based display controller for a local Industrial Equipment manufacturer. The unit included a Vinculum VNC1 USB host controller.

• Re-design of the system controller for the same local manufacturer. Dual CANbus interfaces were implemented. Vehicular environment led to stringent EMC design requirements.

• Controller board (‘HC11) for an on-tractor agricultural device.

In-house projects: building tools and capability.

• Developing a broad line of small breadboarding circuit boards. Product name and mounting method details are private at this time to protect any future patent and/or copyright applications. It can be said that there are presently over 70 board designs in the works, including processors from Microchip, Parallax, TI, Freescale and Atmel. As well, many specific-function analog and digital boards have been designed, built and tested.

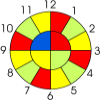

• Low-vision, colour-coded clock. Used a Flash 'HC08 micro. Article in Circuit Cellar issue #159. Also, Java applet and WindozeGUI versions written. For more, see here or click on “My Colour-coded Combinatorial Clock” in the menu under Electronics.

• A custom dual PWM-controlled LED & dual phase-controlled incandescent lamp lighting controller has been built and firmware has been written for its multiple Freescale processors. The need for a table of exponentially rising values led to the PWM step code calculator available on this site.

• Developed a very generic triangle solver using the AJAX paradigm. The AJAX method allows the implementation of “interchangeable solutions” and automatic drawing of the resultant triangle, both of which contribute to good useability. (See the “AJAX Triangle solver” in the main menu under Web or click here .)

• Developed a PHP/MySQL database to keep track of Electronics components. Published in Circuit Cellar. See “EE Components Database” in the menu under Web. The software has been continually evolving in-house.

• Programmed a PID controller to run a toaster oven as an IR reflow oven. Used a surplus 'HC11 board, coded in Dunfield C. The oven has been used for limited production of several designs as well as to produce 1st builds for customers.

• An article on control-shaft electrical encoders was published in Circuit Cellar issue #250,May 2011. The article covers both decoding software (using the smallest PIC family, the PIC10F series) and characteristics of the different device types that are available.

•

An SMD version of the ShareBrained

Chronulator has been built and tested. A variation of the PWM-driven current source was

developed and tested and the board was re-designed to allow either type of source, however the

reality of the market and cost factors caused the deletion of the better design in favour of the

original. This board is available as a product through

ShareBrained  and BC Robotics

and BC Robotics  .

The board is less than 1/4 the size of the TH kit version: the advantage to the ShareBrained

customer is that it will fit in smaller spaces. An on-line calculator, see here, was written to pick resistors for a desired current or to

predict the current range given a set of components.

.

The board is less than 1/4 the size of the TH kit version: the advantage to the ShareBrained

customer is that it will fit in smaller spaces. An on-line calculator, see here, was written to pick resistors for a desired current or to

predict the current range given a set of components.

• A unique POV bike wheel display has been designed and built. Unlike all the other bike-wheel POV displays, this one is aimed at cycling safety. A re-design is in the works to use double AA cells and a boost regulator instead of a 9 V battery and a buck regulator.

• Using an XuLa FPGA board, I've been experimenting with a 24-channel, 16 bit resolution PWM. This is based on the observation that 8 bit PWM intensity control is not sufficient when the full range of our visual system is taken into account.