The L'ilBoard mounting arrangement:

cheap, versatile and flexible.

The basic arrangement:

- The board sizes are such that they mount between 1.0" (25.4 mm) centers;

- The smallest size is 25.0 mm×25.0 mm. I call that a 1×1;

- 1×2 and 2×2 sizes are produced as well;

- Larger sizes can easily be designed;

- Boards can be placed in any one of four rotations;

- Mounting hardware can be, in order of increasing size, any of: M2, #2-56 UNC, M2.5, #4-40 UNC or M3.

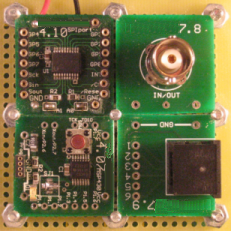

Photo 1 shows a section of perfboard, drilled then with hardware installed. Next, 4 modules were added. With #4-40 or M3 hardware there is some natural spring pressure keeping boards installed, in this case usually only connector boards need nuts to hold them down firmly.

Photo 1.

Left: Just the nuts and bolts. The circle at top right of the image is a

self-stick felt pad being used as a foot. Right: A processor, an SPI port and a couple of

connectors pushed in.

Photo 1.

Left: Just the nuts and bolts. The circle at top right of the image is a

self-stick felt pad being used as a foot. Right: A processor, an SPI port and a couple of

connectors pushed in.

Perfboard is convenient as a base, however any flat material that can be drilled through can be used. The bottom side of a project box can be used, as can an Altoids tin. Thicker materials can be drilled and countersunk for flat head screws so that screw heads don't protrude.

There is nothing requiring the screws to be pointing upwards. If you want to drill and tap holes into some thicker material and drive the screws into the material that works just as well! A nut or spacer of some kind will certainly be needed: its length depends on requirements.

Photo 2 shows a headphone amp which shows another feature: the boards can be stacked.

Photo 2.

Left: A little headphone amp. Right: Boards stacked with #4-40 M-F spacers.

Photo 2.

Left: A little headphone amp. Right: Boards stacked with #4-40 M-F spacers.

Photo 3.

A shot of the corner of a board where bolts have been mounted in both directions. The standoff

raises the boards.

Photo 3.

A shot of the corner of a board where bolts have been mounted in both directions. The standoff

raises the boards.

When packing density needs to be increased and stacking won't help, boards can be mounted on both sides of a piece of perfboard and threaded spacers used as legs, Photo 3. It is better to use countersunk screws in this arrangement, though, which implies thicker materials.

As needed, larger holes can be drilled between the mounting holes to allow wires to pass through the perfboard.

3D printed platforms:

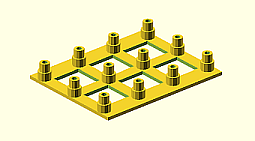

Recently, I have been making 3-D printed platforms for the L'ilBoards. I use OpenSCAD as my 3D modeller of choice, so it is easy to make the designs parametric. Image 1 shows a sample rendering, with its code as a link, and Photo 4 shows a collection of some of my 3D printed platforms.

The rendition shown in Image 1 is a newer idea, where I designed the posts to hold nuts captive. All the platforms in Photo 4 required that the posts be tapped for #2-56 screws, which was quite a tedious job!

At the bottom left of the photo the 2 black platfoms represent an idea that sections which connect together can be made. This idea still needs refinement.

All in all, a very versatile system.